TPAC, global specialist in Ultrasonic NDT Solutions!

Our product LINES

Explorer – Device for Phased Array Ultrasonic Testing

Getting you the right solution

is our mission at TPAC!

Whether it is a standard or tailor-made solution, from the most standard to the most NDT Ultrasonic applications.

You tell us what your challenges are, we will build the most adapted offer based on our unique offering: product portfolio, know-how, and the widest range of technologies. We are your personal NDT specialists.

Download our NEW brochure

Discover at a glance who we are and what we can offer to you

Our mission

At TPAC, it's not just about technology; it's a partnership for YOUR inspection success!

-

Unlocking success together

Discover YOUR own Ultrasound NDT solution with our experts - Your needs, your financial plan We match you with the right system, tailored to your needs

-

Tailored solutions, when needed

Whether standard or custom, our expertise ensures a perfect fit for your goals -

Partnership beyond products

We prioritize rapid progress in your projects to build lasting partnerships, not just providing solutions -

Direct support

Need help? Reach out. We are here to provide a clear understanding, ensuring you are never alone

Fit to needs

Budget matching

Expertise

Performance

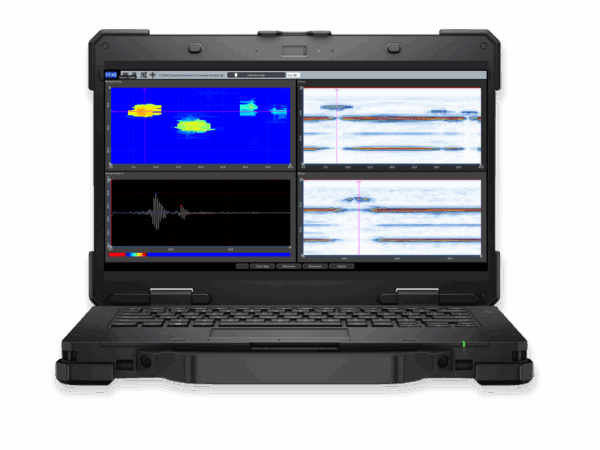

Explorer : a complete PAUT and FMC/TFM platform

TPAC introduces the Explorer Series, a new generation of Phased Array and FMC/TFM instruments built for performance, speed, and flexibility.

Compact, powerful, and ready for any challenge, the Explorer platform sets a new benchmark in advanced ultrasonic imaging.

News & events

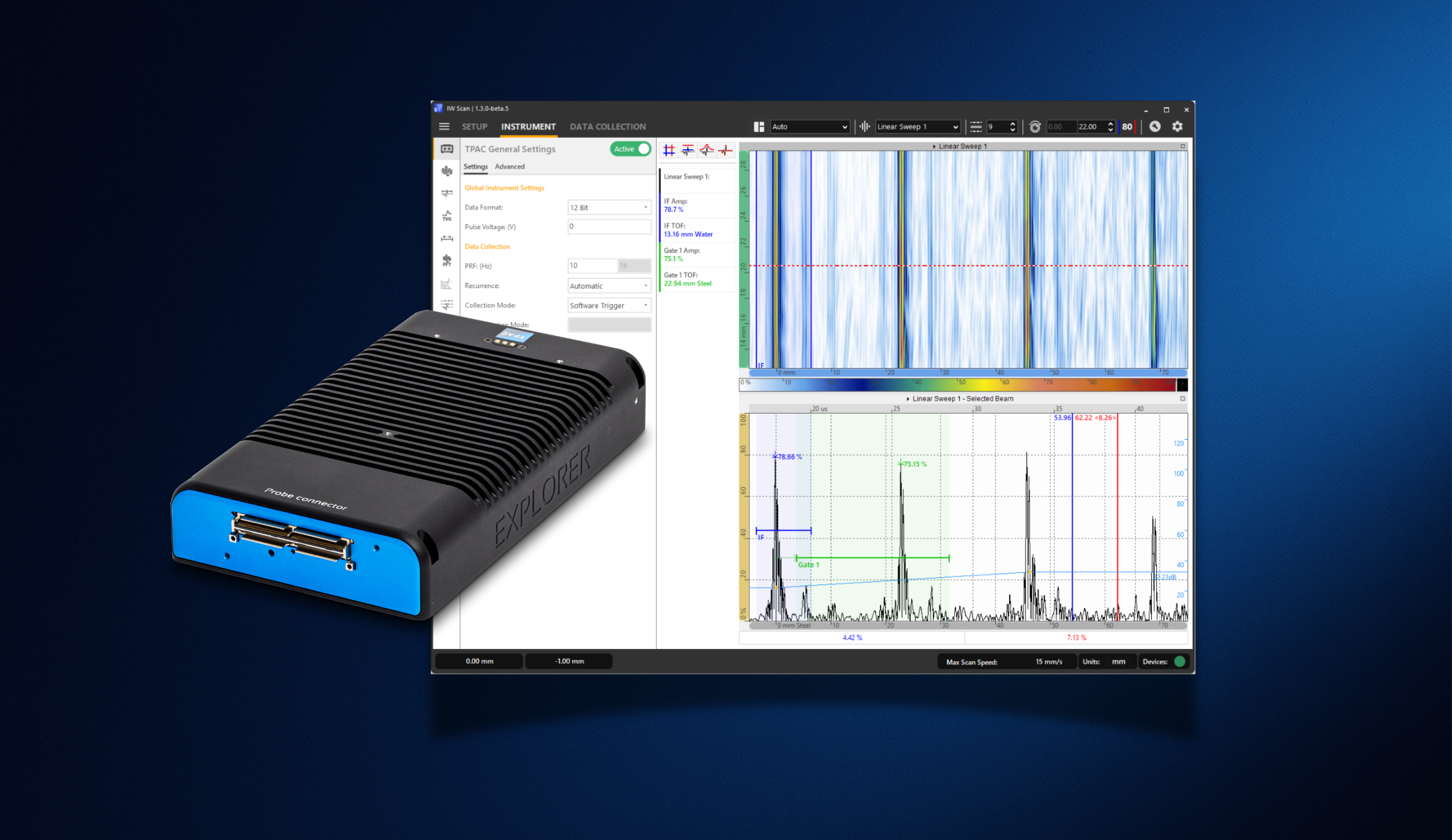

TPAC Explorer Now Supported in IW Scan by UTEX Scientific

Explorer is fully compatible with IW Scan, allowing users to collect and visualize data directly within UTEX’s software environment.

Everything You Need to Know About the ASNT Conference 2025 in Orlando

Discover TPAC’s expertise in linear array probes for NDT, from design and applications to advanced techniques for precise, reliable inspections.

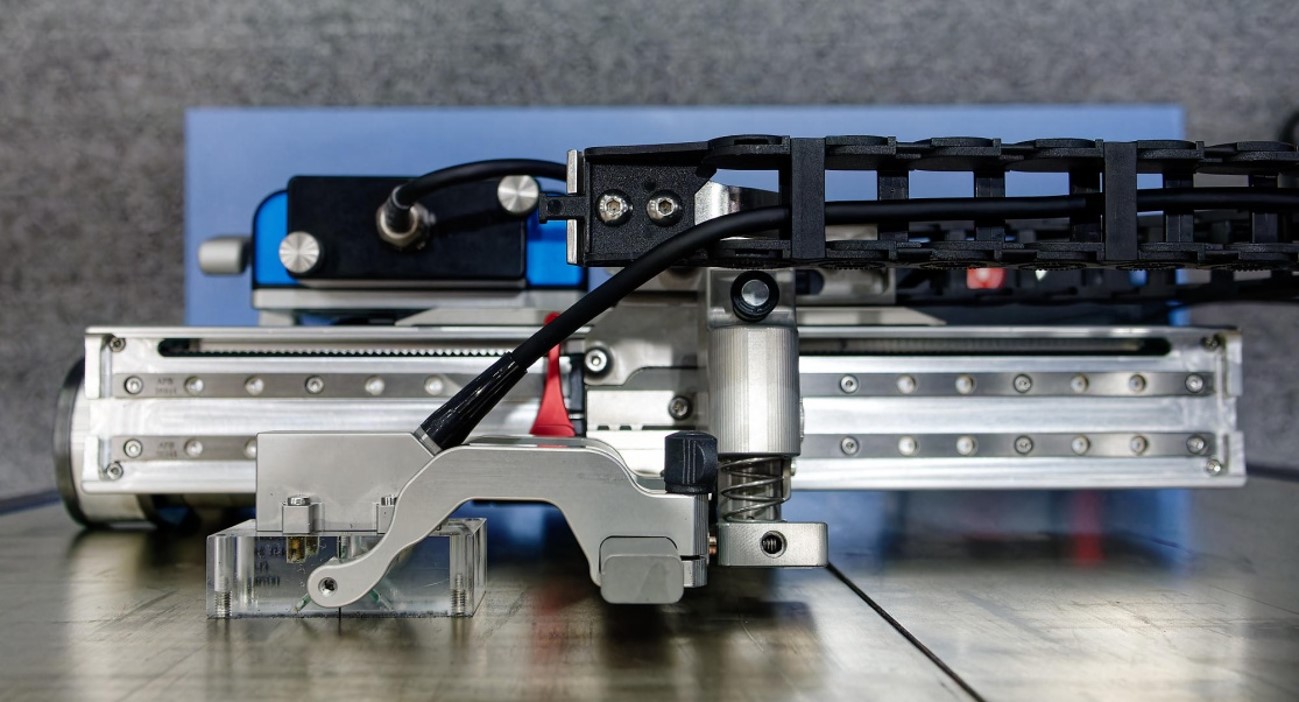

Linear Probes in NDT – Capabilities and TPAC Expertise

Discover TPAC’s expertise in linear array probes for NDT, from design and applications to advanced techniques for precise, reliable inspections.

Neuronal

organization

Prime support

worldwide

Culture diversity

beyond language

Driven by

Customer satisfaction

Top experts,

Physics, App

International scientific

publications

Contact us