Applications

OUR VARIOUS RANGE OF APPLICATIONS

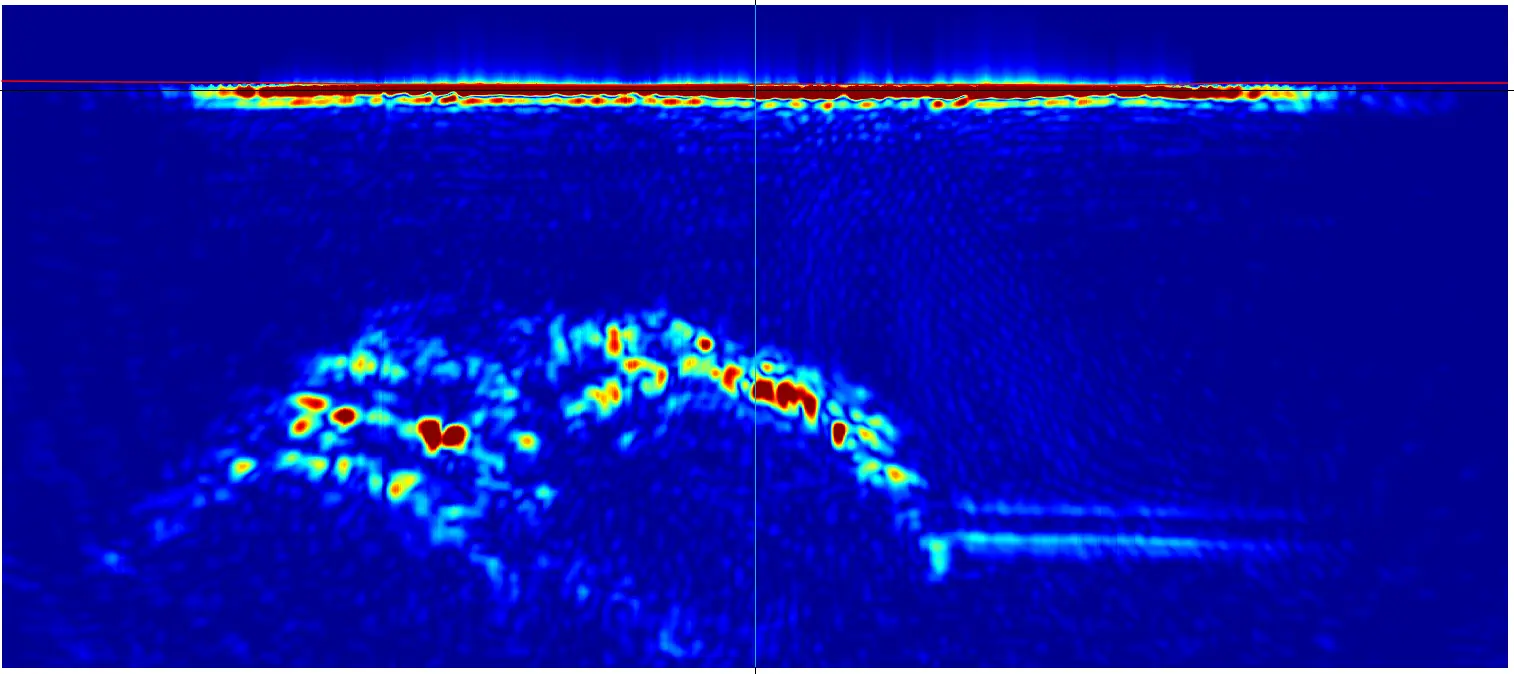

Weld Inspection

The welding process can produce flaws dueto the metallurgical changes a material undergoes when exposed to heat or because of inaccurate weld parameters. TPAC offers the tools to inspect successfully butt welds, fillet welds, and other configurations found in pipelines, pressure vessels, structural components, or more.

Corrosion Mapping

Corrosion is everywhere. Whether it comes from hydrocarbon corrosiveness, impurities, electrochemical reactions, humidity, the range of industries affected is extensive. By choosing TPAC’s solutions, industries can proactively extend the lifespan of assets, and ensure safety with real-time assessment, minimizing downtime and costly repairs.

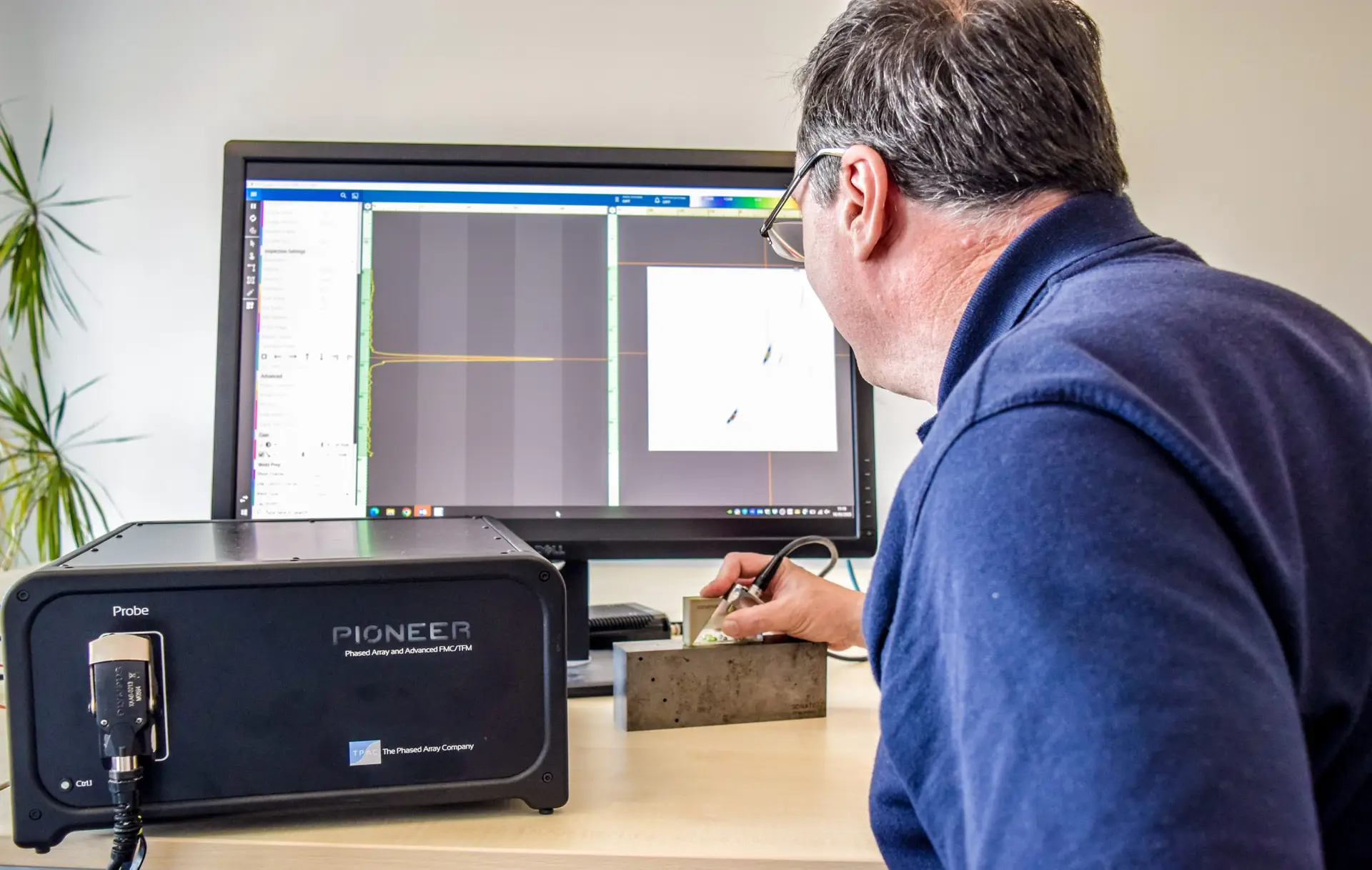

Field Inspection

For NDT technicians performing onsite inspections TPAC offers cutting-edge UT technology such as phased array, Plane Wave Imaging (PWI), Total Focusing Method (TFM) and even Phase Coherence Imaging (PCI). Whether it’s for pipelines, storage tanks, jet engines, railways, or nuclear power plants, TPAC solutions are field-ready.

Composite Inspection

The unique structure of composite materials result in specific defects such as delamination, porosity, or multilayer disbond. TPAC provides cutting-edge technology to meet composite inspection challenges including for high-attenuative materials (as thick honeycomb-CFRP sandwich-structures), dry inspections (using air-coupled UT), and complex shapes.

Inline Inspection

Inline inspection is a key control tool in the manufacturing process to ensure reliable product quality for tubes, bars, plates, and many other metal fabrication industries. As quality standards and testing specifications get more demanding, TPAC’s portfolio of advanced electronic offer allows to retrofit existing installations whether to conventional UT or PAUT technologies.

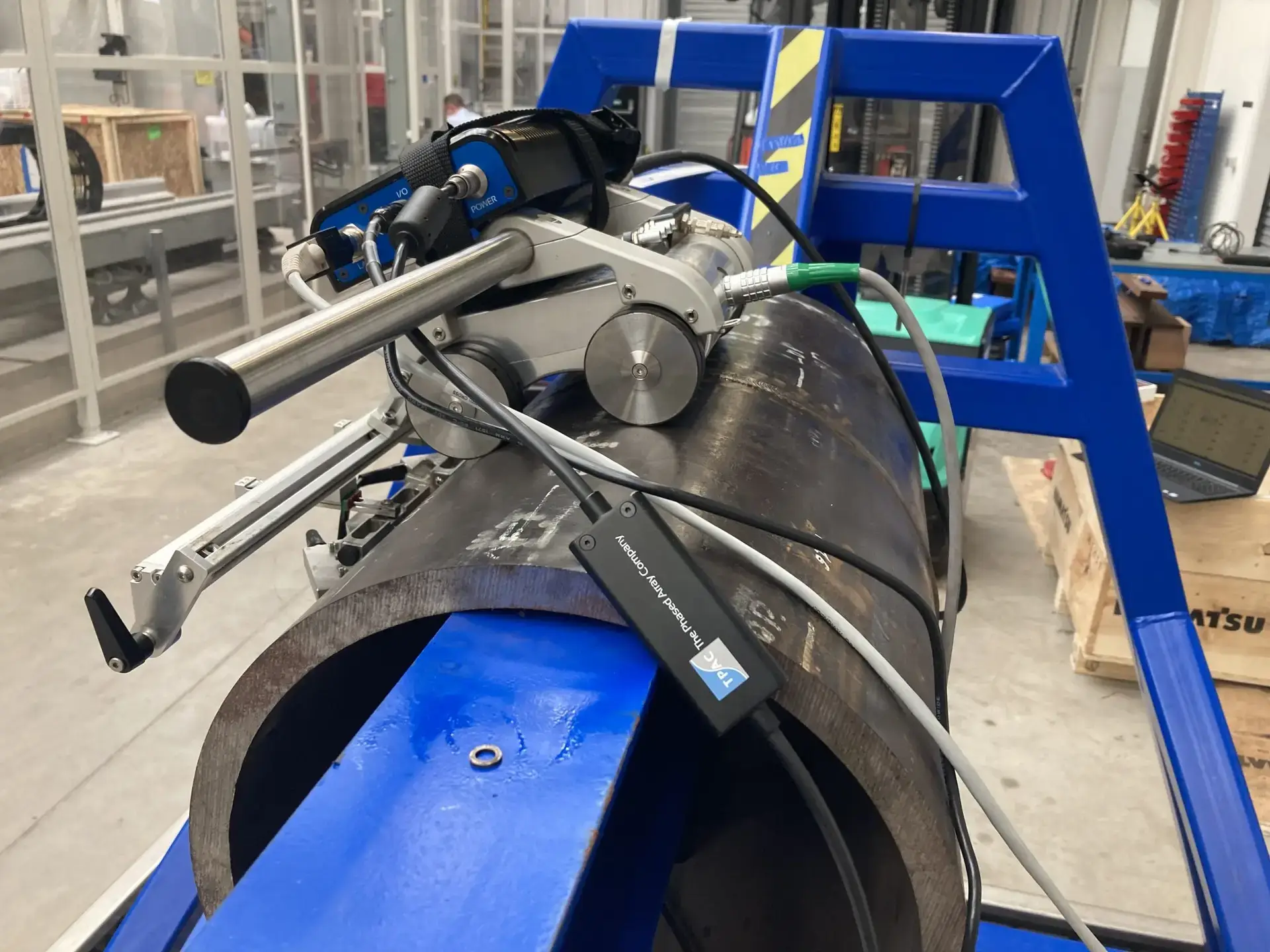

Robotic Application

The growth in use of industrial robotics has provided an interesting new approach to solving ultrasonic testing applications. TPAC’s solutions for robotic ultrasonic testing increases speed, improves efficiency, accuracy, and safety, paving the way for more reliable and cost-effective inspection solutions across diverse industries.

Research in ultrasound

TPAC has a long history of providing ultrasound instruments for research. While developing a wide ultrasonic portfolio of software and hardware, our team has developed a large variety of data acquisition and imaging/beamforming techniques. As a result, we offer an Application Programming Interface (API) with all our equipment for you to freely conduct your own research.

Matching your needs

Your needs are unique to your application

It requires a deep understanding of testing technology to provide the right system for the right application within the right budget.

Unlike many companies, we offer our standard solutions only if they fulfill your needs.

Our unique expertise and know-how allow us to identify the most adapted solution to achieve your goal.

For us, it’s more than just ensuring safety. It’s about fostering confidence, versatility, high performance, together with ensuring that our solutions are easy to use and understand.

We provide peace of mind, enabling you to progress fast, reduce risks, all these for the LONG TERM!