The development of multi-element probes has favored the generalization of ultrasonic imaging methods for non-destructive testing (NDT). The reconstruction of a spatial image from temporal multi-element data is called beamforming. Early ultrasonic signal measurement electronics were limited in terms of data throughput. The beamforming operation was generally carried out by the hardware in order to limit the amount of data returning to the computer. Unfortunately, the quantity and diversity of operations that it is possible to achieve with the hardware are limited and the beamforming operations have to remain very simple. In most cases, the Delay-and-Sum (DAS) method is employed. It simply consists in delaying the signals with proper time-of-flight before summing them. The quality of images reconstructed with DAS is limited. For instance, the inspection of coarse-grained or highly attenuative materials may become very difficult. Moreover, the images can be affected by side lobes, grating lobes or reconstruction artefacts. Nowadays, ultrasonic devices are more and more powerful and can achieve fast data transmission. It is possible to transfer the complete radio-frequency data measured by the probe to the computer. Then, the question is why do we still limit ourselves to standard DAS methods?

Towards various beamforming methods

Radio-frequency data are very rich and contain a lot of information. It is clear that there are more effective ways to reconstruct an image than standard DAS. Since the complete data set is collected by the computer, the range of data processing possibilities seems endless. During the definition of the inspection strategy, the acquisition of raw data enables to do post-processing and to test which reconstruction method is the best based on the specificities of the application. Depending on these results, one or several beamforming methods could be selected for the final industrial inspection. If the computation time of the selected methods is compatible with the inspection speed, several reconstructions could be performed simultaneously in real time. Another option could be to apply more advanced and demanding techniques only if something suspicious is detected on the standard reconstruction. Then, the significant criteria for software beamforming appear to be the computation time and the imaging quality. The computation time is continuously improved by the increase of computer and Graphic Processing Unit (GPU) processing power. The imaging quality is also constantly evolving because new beamforming methods can be quickly integrated to existing software or can be used to process historically stored data.

Recent growth of coherence beamformers

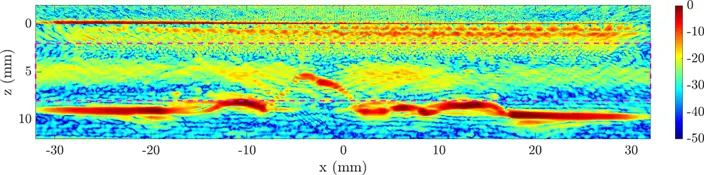

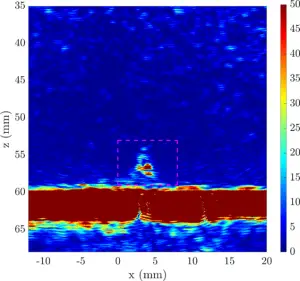

Coherence beamformers have recently gain in popularity because they generally provide a good image quality with limited additional computational cost. Delay-and-sum techniques naturally highlight coherent information coming from a reflector compared to incoherent signals that can be due to electronical or material noise. It could probably be considered as the simplest coherence beamformer. The idea behind the so-called “coherence beamformers” is to reinforce the coherent summation compared to standard methods. The principle is to measure the coherence of received signals based on various measurements (phase, sign, amplitude) and to include this additional information into the coherent summation. Many coherence beamformers have been developed over the last decade. Phase Coherence Imaging (PCI) has become the most popular of them and shows great results on typical NDT challenges such as the characterization of HTHA (High temperature hydrogen attack) defects or the detection of cracks. Figure 1 is showing a comparison between standard Total Focusing Method (TFM) reconstruction and PCI. The Full Matric Capture (FMC) data have been collected on a steel sample containing a fatigue crack shown in Figure 2. This result is showing that PCI performs very well on diffraction echoes.

| (a) | (b) |

|

|

Figure 1 : Ultrasonic images of a crack. The images are in linear scale and normalized at 50 % of the maximum crack amplitude (pink area). (a): TFM reconstruction. (b): PCI reconstruction.

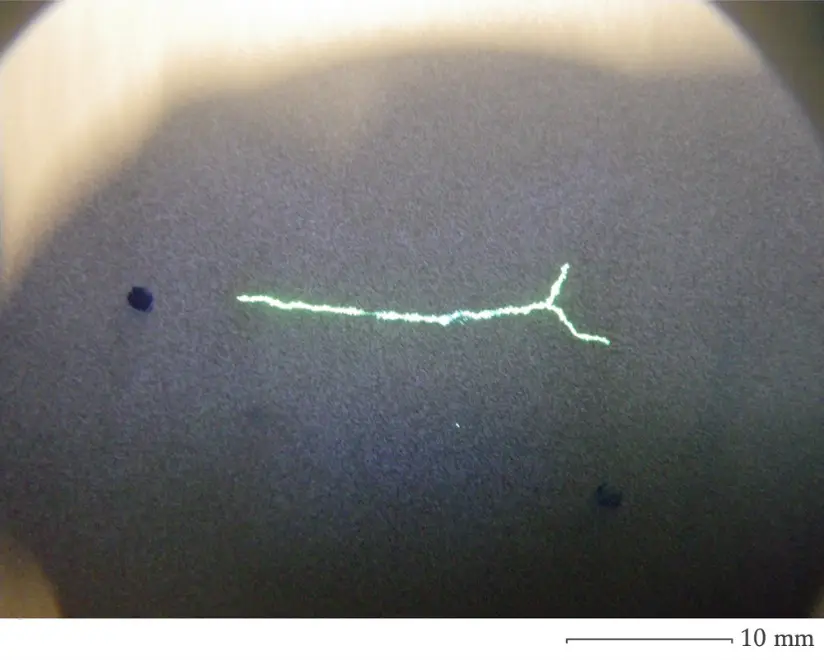

Figure 2 : Bottom view of the sample containing the fatigue crack.

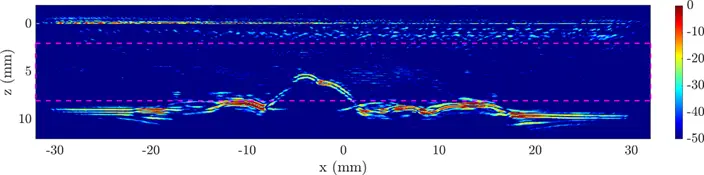

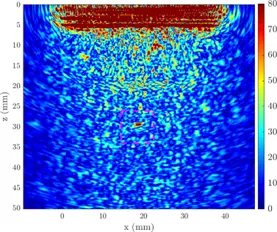

Although applicable in real time, the PCI still requires extra computation compared to TFM because the phase information has to be extracted from the data. In case of very fast inspection, other coherence beamforming methods that requires less computational resources have been developed. Figure 3 shows an example of corrosion in a steel sample inspected with plane waves. The acquisition of plane waves is very fast compared to FMC and a fast reconstruction method is required in this case. The image shows an amplitude coherence beamforming technique that has similar computational complexity as standard DAS and can therefore achieve an inspection speed of several kHz. This method is performing quite well on the corroded samples with a greatly improved contrast.

Figure 3 : Ultrasonic images of a corroded steel plate. The images are normalized by the maximum of the pink area and displayed in logarithmic scale with 50 dB of dynamic. (a): Plane waves reconstruction. (b): Reconstruction with amplitude coherence method.

Accounting for the ultrasonic waveform

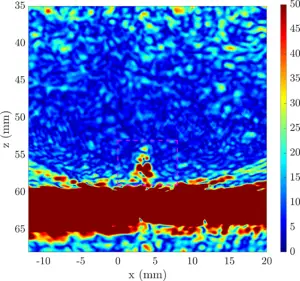

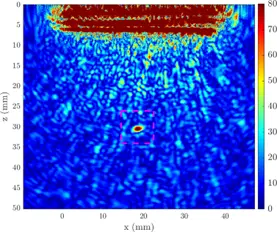

Coherence beamforming methods do not account for the shape of the ultrasonic waveform propagating in the medium. Though, there are many different signal processing tools that can help to improve the reconstruction when the pulse shape is known. For example, cross-correlation techniques are known to improve the signal-to-noise ratio when a defect signal is embedded in noise. Figure 4 shows an example of machined defect detection in a coarse-grained steel from the nuclear industry. The defect is a side drilled hole of 0.4 mm diameter and is located at 30 mm. The inspection is performed with a 5 MHz probe and is using FMC modality. The reconstruction that accounts for the ultrasonic waveform is showing an improved contrast in Figure 4 (b) compared to standard TFM in Figure 4 (a).

| (a) | (b) |

|

|

Figure 4 : Ultrasonic images of a crack. The images are in linear scale and normalized at 80 % of the maximum SDH amplitude (pink area). (a): TFM reconstruction. (b): reconstruction accounting for the pulse shape.

It is true that this requires an extra modelling effort to account for the ultrasonic waveform. This can be considered as a calibration procedure which is already common in NDT and where the waveform would be estimated on known reflectors. This type of techniques will also benefit from latest generation of ultrasonic devices that are able to modulate the excitation signals of emission. Indeed, longer excitation signals greatly increase the amount of energy transferred to the media and therefore, the potential gain in signal-to-noise ratio. Again, this cross-correlation technique is only one example among a wide range of possible applications. Based on an accurate modelling of the waveform and propagation model, deconvolution techniques can be envisaged to increase the resolution of ultrasonic images.

Conclusion

The purpose of this article is to show that the possibility to process ultrasonic data by a computer offer numerous possibilities for NDT. A lot of processing techniques could be imagined but each of them has its advantages and drawbacks. The processing method has to be adapted to the application constraints depending on the imaging quality (contrast, resolution), the detection problematic (material, sough defects) and the inspection speed.