Nonlinear acoustics

Nonlinear acoustics is now available for research and industry thanks to ultrasonic phased arrays.

See the invisible

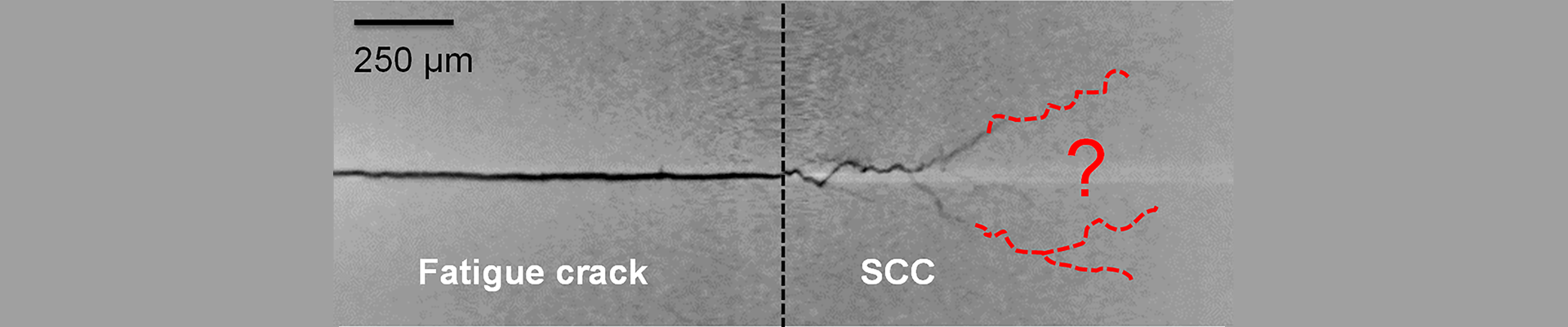

The detailed characterization of cracks is a major challenge in various nondestructive testing (NDT) applications. Stress Corrosion Cracking (SCC) is an example of a cracking damage mechanism that can be difficult to image, and must be detected as early as possible.

Crack detection and sizing is usually performed by conventional or phased array ultrasonic testing. Actually, these NDT techniques, make linear acoustic assumptions (impedance mismatch in the material), only reveals the “opened” parts of cracks. In too many cases, full or partial closing of a crack therefore leads to difficulty in defect detection. In order to overcome this issue, TPAC has focused on improving crack characterization by detecting and measuring closed parts.

It is well known that “closed” cracks generate nonlinear signatures. The historically available methods to manage nonlinear acoustics were difficult to apply in practice. Based on high-level academic collaborations, TPAC has developed imaging techniques using array probes that can visualize nonlinear signatures at the same time as the linear response. This technique works in real-time and can be used for part scanning in real situations in an efficient way withstandard equipment.

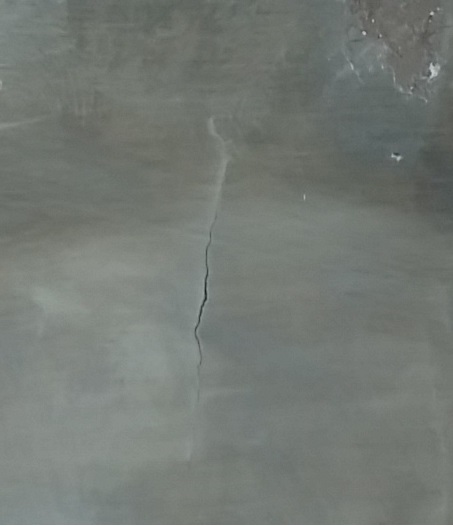

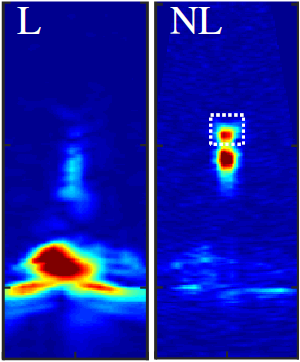

The presented example shows the inspection of a fatigue crack inside a stainless steel sample. The linear and nonlinear images given by our software are displayed here. The linear image (on the left) shows the root geometry and opened part of the crack. The nonlinear image (right image) is highly sensitive to closed parts and tip of the crack.

This method has great potential in many applications in power generation, aeronautics, and others.