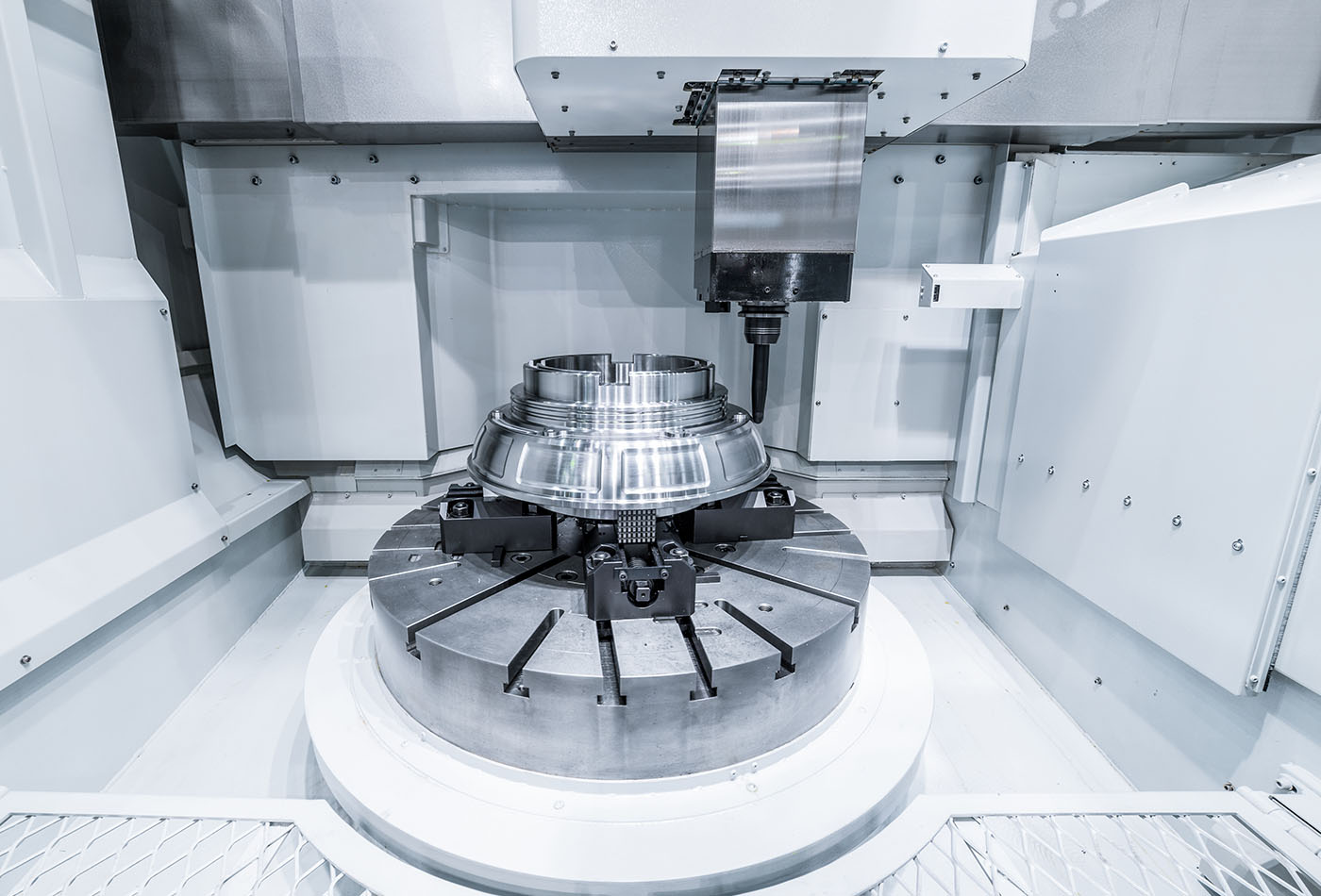

Elaboration, forging, machining

Support for statistical process controls and quality check solutions for manufacturing.

Reducing Manufacturing Cost

TPAC NDT brings value to aeronautical meta processing by installing detection capabilities as early as possible. The unique integration ability of the UT hardware makes it possible to install UT equipment as close as possible to the probes. Also, the UT equipment is easily integrated into existing gantries, immersion tanks, or robots in the NDT shop, as well as earlier stage processes like routing, cleaning, metrologic systems, and many others. TPAC products perfectly fit into a lean manufacturing transformation.

Our New UT technologies provide industrial grade performance, and are a game changer for satisfying more stringent detection criteria, and dramatically cutting inspection time.

- Make multizone inspections for thick parts fast and highly sensitive.

- Reduce near-surface dead zone and increase sensitivity to reliably inspect forged sonic parts.

- Inspect machined, molded, and cast parts, with clear imaging of indications and geometry.

- Volumetric indications and crack detection in superalloys (Ni, Ti).