Solid axles

Rails, Railways and Rolling Stock

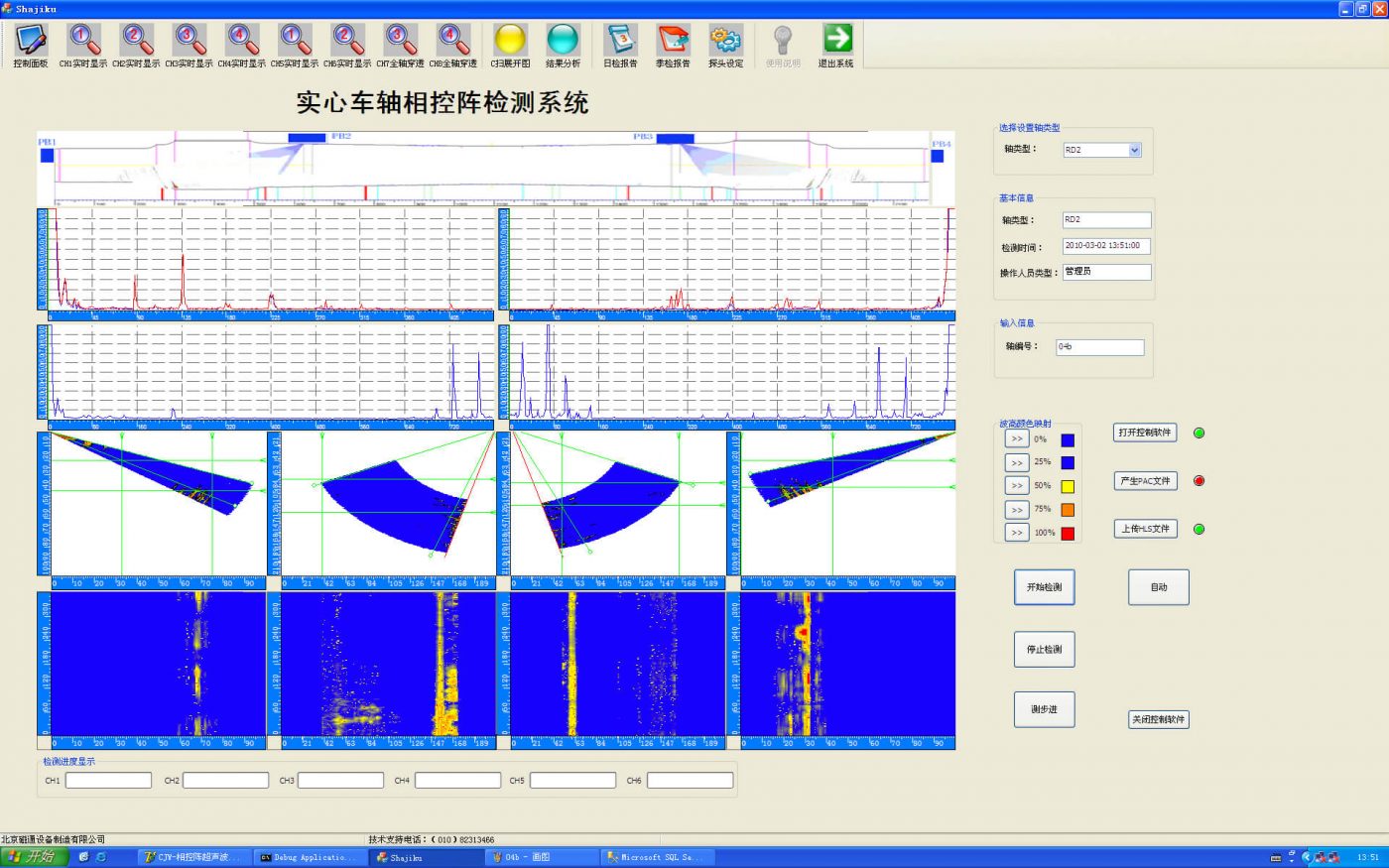

Manufacturing and maintenance solid axles inspection

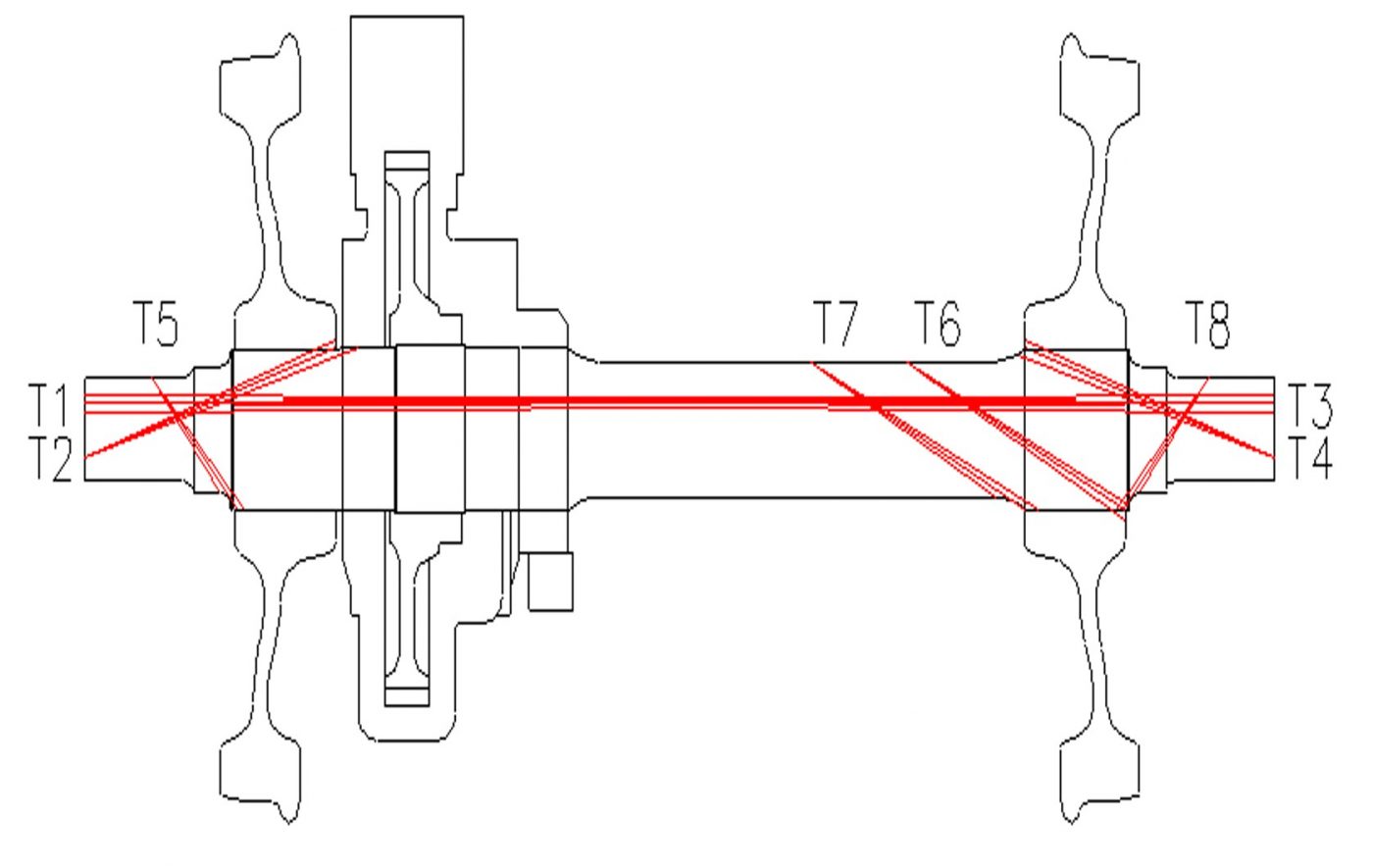

Inspection of solid axles, whether during the manufacturing process or in-service, is complicated…but essential. Passengers and freight have a many different configurations – with varying access to do the inspection – that typically requires journals, wheel seats and middle section inspections.

Detectability, accuracy, and inspection time are key factors. TPAC provides the options for you to select the right answers to your requirement.

Inspection without removing the wheel and the bearing is usually necessary to avoid complicated and time-consuming material handling. Depending on the country’s standard, and the location of the flaws, the inspection target can be as low as 0.5mm height in the wheel seat area, for example. The noise provided by the wheel or the bearing shrink-on makes the inspection quite difficult.

TPAC provides a large range of solutions among which you can select the exact right configuration for your case.

Solid Axles manufacturing inspection

You want to increase the productivity of your inspection without compromising on the quality. TPAC proposes a few options that will meet your requirements, and also within your budget. All the complexity of the inspection is managed by the TPAC equipment and software, unless you like to use your own, which we can easily support.