Field Inspection

Powerful and field deployable advanced ultrasound equipment

TPAC provides both powerful and field deployable advanced ultrasound equipment. Non-Destructive Testing (NDT) relies heavily on ultrasound technology to ensure the safety and integrity of various structures and components that are in use and cannot be removed for inspection. Examples include pipelines, welded joints and piping, storage tanks, airplane structures, jet engines, railways, fossil fuel plants, and nuclear power plants. As these components cannot be moved for inspection, NDT technicians have to travel to on-site where they are in use, which can often be outside in the elements and in touch environments.

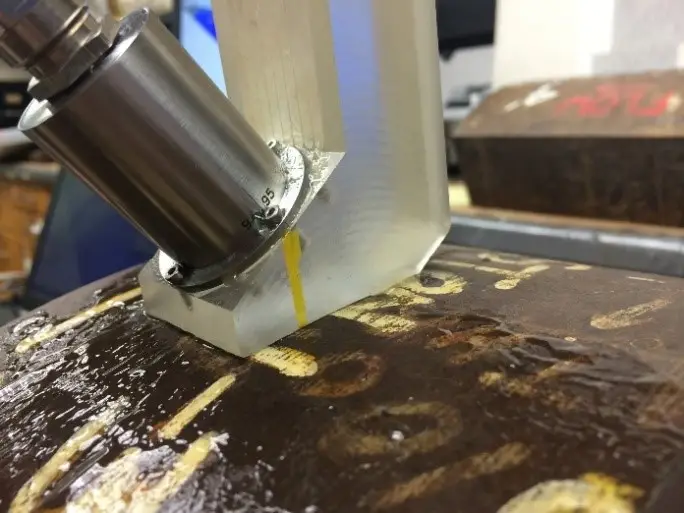

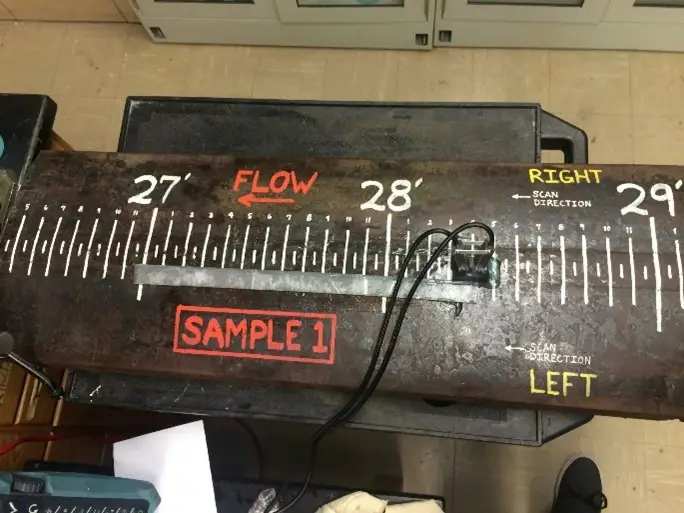

Figure 1: HEP Test Sample – an example of a 128 element tightly focused probe designed for use in high energy piping inspection in an effort to both detect and evaluate the different stages of creep damage.

Cutting-edge ultrasound technology for challenging environments

When it comes to field inspection, TPAC offers cutting-edge UT technology such as phased array, Plane Wave Imaging (PWI), Total Focusing Method (TFM) and even Phase Coherence Imaging (PCI) that can be used for typical field applications like Corrosion Mapping, Weld Inspection and more specific damage mechanisms like Creep and HTHA

For more please see :

Our solutions for field inspection – The Explorer line

Engineers at TPAC have spent countless hours perfecting the packaging of the Explorer line of ultrasound equipment to account for field conditions. Often in the electronic and instrumentation industry high performance and speed often comes at the expense of “large”, meaning more electronics, which comes with higher power consumption. The Explorer is really a win-win phased array instrument where TPAC has achieved the best of both worlds, where the NDT industry can have both extraordinary performance in a compact and low power design. This allows inspection service companies to deploy TPAC’s latest inspection technologies by providing a compact, lightweight, low-power, and rugged instrument that is powerful and highly performant but easily transportable and quick to set up.

Imagine being able to eliminate long, expensive and complicated umbilical phased array probe cables that can diminish data quality, easily break or get caught in structures. With a small form factor, IP67 rating and being lightweight you can easily mount the Explorer directly on your robot, scanner or automated system. This allows you to keep your probe cable short and simple, ensuring the best signal quality.

Key features of the Explorer Product Line

- Channels: 16/128, 32/128, 64/64, 64/128, 128/128, 64/256...etc.

- Designed for IP-67

- Lightweight = less than 4 lbs.

- Low power consumption

- Wide Bandwidth: 50 kHz to 20 MHz (unique low frequency capability!)

- Excellent gain range: 12~110 dB

- High PRF: 20 kHz

- Supports up to 100m between the Explorer and a PC running the acquisition software

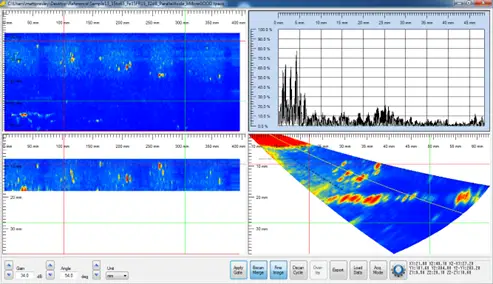

Figure 2: Example Phased Array Image using TPAC’s Prelude Software

Our solutions for field inspection – Prelude Software

TPAC’s Prelude software for weld inspection can be easily installed on a standard laptop, which offers several advantages. Firstly, having the data already on the same laptop that the analysis will be done on saves time. Secondly, disassociating the screen with the unit allows you to mount the instrument on the scanner. Lastly, laptops are constantly improving, so you can take advantage of the latest processing ability of laptops without having to replace the entire phased array instrument. Instead, you can simply upgrade to a new laptop to improve inspection speed performance.